Interpreting a Public NLJD Performance Standard:

GA 1236-2015 from China

Introduction

In the professional global TSCM market, objectively evaluating and comparing the performance of different Non-Linear Junction Detectors (NLJDs) has always been a challenge for most users. Few operators will hold different NLJDs on hand and make on-site performance comparison. Unlike countries such as the USA and Russia, which typically use non-public, internal standards, China’s GA 1236-2015 standard is one of the few official standards in the world that is publicly available, comprehensive in detail, and includes clear performance grading.

The purpose of this article is not to claim that one standard is superior to another, but rather to share this public standard as a valuable reference framework and technical case study with our global TSCM peers and professional clients.

Through this interpretation, you will gain an understanding of how a rigorous, quantifiable NLJD performance evaluation system is constructed. Regardless of which brand of product you ultimately choose, we believe that mastering this knowledge will help you make a more informed and professional purchasing decision.

Core Point 1: Quantifiable Performance Grades

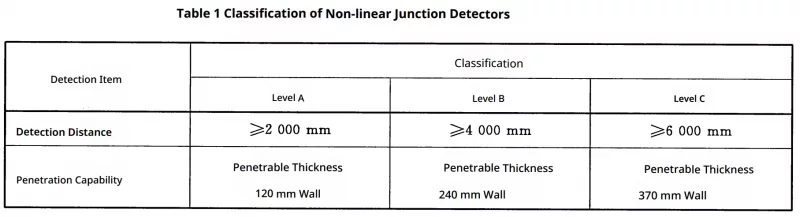

The most crucial part of the GA 1236-2015 standard is its establishment of three performance grades, from low to high. This classification is based on two of the most critical metrics that reflect a device’s real-world capability: detection distance in open space and penetration capability through a standard wall.

This grading system provides users with a simple and intuitive basis for judgment. If a device achieves a Class C certification, it means its open-space detection distance and its ability to penetrate a standard brick wall have met the highest national standards, signifying its power and sensitivity have passed the most stringent tests.

Official Standard Excerpt: Performance Grade Table

Note: Please note that the Class C standard requires the device to detect the target after penetrating a 370mm (37 cm) thick standard brick wall. This is the toughest benchmark for measuring a device’s maximum penetration capability.

Core Point 2: The Scientific & Unified Test Basis

The biggest confusion customers face in practice is: “Why is the detection distance for a hidden pinhole camera different from what you advertise?” The GA 1236-2015 standard perfectly answers this question.

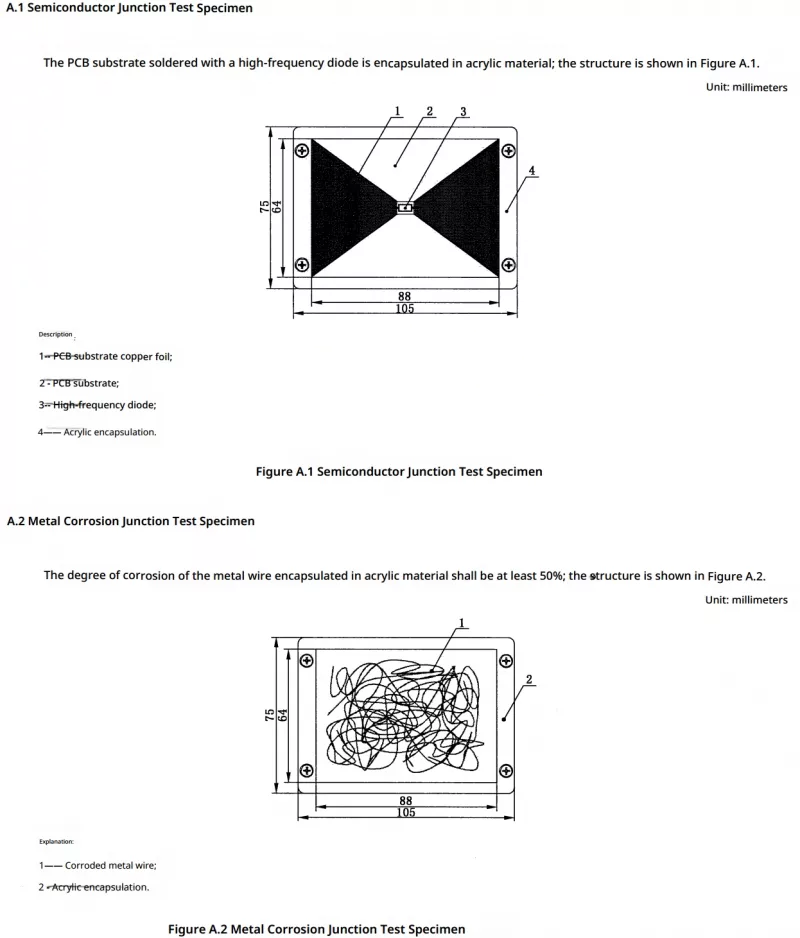

The standard mandates that all performance tests (including detection distance and penetration) must be conducted using a unified “semiconductor junction standard test specimen”. This is a “bare, non-shielded” ideal target, specifically designed to measure the maximum performance of a device. This ensures that all equipment is compared under identical, fair, and repeatable conditions.

Any real-world electronic device (like a pinhole camera or a voice recorder) has varying degrees of RF Shielding, which will significantly reduce the NLJD’s detection range. Therefore, detection distances obtained using real-world devices cannot objectively reflect the intrinsic performance of the NLJD itself.

Official Standard Excerpt: The Foundation of Scientific Testing

Note: All officially certified performance data must be based on detecting this “bare, non-shielded” standard test specimen. Any detection distance data obtained using real-world electronic devices cannot be used as a scientific basis for comparing the performance between different devices.

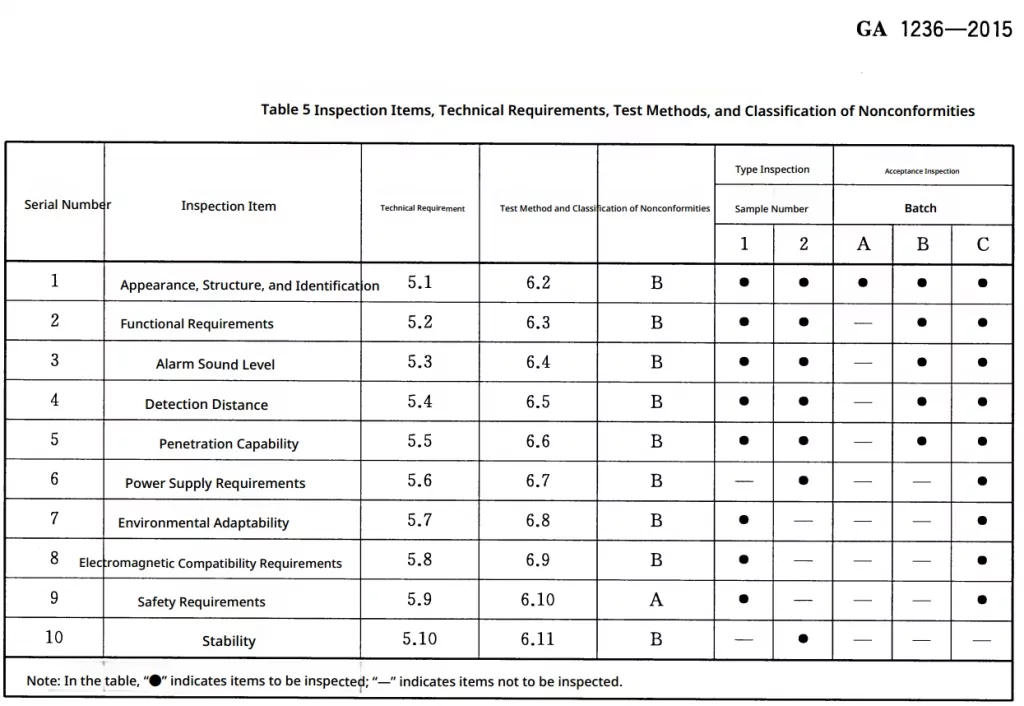

Core Point 3: Comprehensive Reliability Requirements

The essential difference between a high-level instrument and a low-level one lies in its reliability in complex environments. Beyond performance, GA 1236-2015 sets mandatory requirements for a professional device’s environmental adaptability, electromagnetic compatibility (EMC), safety, and stability.

For example, the device must operate normally under harsh conditions such as high temperature (+55℃) and low temperature (-10℃); it must resist interference from static electricity and strong electromagnetic fields without producing false alarms; and it must be able to operate continuously for 168 hours without failure. This defines the reliability benchmark for a professional device to be fail-safe in mission-critical situations.

Explanation of what condition and how to do?

6.1 Test Conditions

Except for climatic environmental tests, all other tests specifed in this standard shall be conducted under normal atmospheric conditions:

– Ambient temperature: 15 ℃ to 35 ℃;

Relative humidity: 25% to 75%;

Atmospheric pressure: 86 kPa to 106 kPa.

5.4 Detection Distance

The detection distance of non-linear junction detectors, under conditions of maximum receiving sensitivity and maximum transmitting power, shall comply with the clarification requirements specified in Table 1.

6.5 Detection Distance Requirements (How to do)

Using the semiconductor junction test specimen specified in Appendix A, slowly move the nonlinear junction detector along the normal direction of the test specimen surface from far to near until the detector issues an alarm indication. Record the distance between the test specimen and the nonlinear detector, and determine whether it complies with the requirements of 5.4.

5.5 Penetration Capability

The penetration capability of non-linear junction detectors, under conditions of maximum receiving sensitivity and maximum transmitting power, shall comply with the classifcation requirements specified in Table 1.

6.6 Penetration Capability (how to do)

The brick wall shall be constructed using first-class clay bricks with a strength grade of MU15 in accordance with GB 5101—2003. The length and height of the wall shall each be no less than 1 m, with wall thicknesses of 120 mm, 240 mm, and 370 mm, respectively. Fix the semiconductor junction test specimen specified in Appendix A to the center position on the back of the wall. Use the nonlinear junction detector to perform detection at the corresponding position on the front of the wall to determine whether the requirements of clause 5.5 are satisfied.

Conclusion: Why Understanding a Public Standard is Crucial

The GA 1236-2015 standard provides us with a valuable window into how to transform the various capabilities of an NLJD from vague “feelings” into clear “data” and “grades.” It emphasizes the importance of scientific and fair testing using a “standard test specimen” and points out that the factors determining a device’s true reliability go far beyond just detection distance. Mastering this knowledge can help any non-professional user make a more informed and robust purchasing decision.

Download This Guide

Save this complete guide for your reference. This document provides a professional analysis of the GA 1236-2015 standard key points and its implications for evaluating NLJD performance.

(PS: Original copy is released by People’s Republic of China Public Security, Published and Distributed by China Standards Press.)

Experience Our Professional NLJD Products Built on a Top-Tier Technology Platform

Discover how a device, designed and manufactured to strictly adhere to and exceed demanding performance standards, can provide unparalleled assurance for your security missions.

Learn More About DT-810 Professional NLJD for governmental projects

Learn More About DT-824S New NLJD integrated with Audio Mode